Advanced & Technical Ceramic

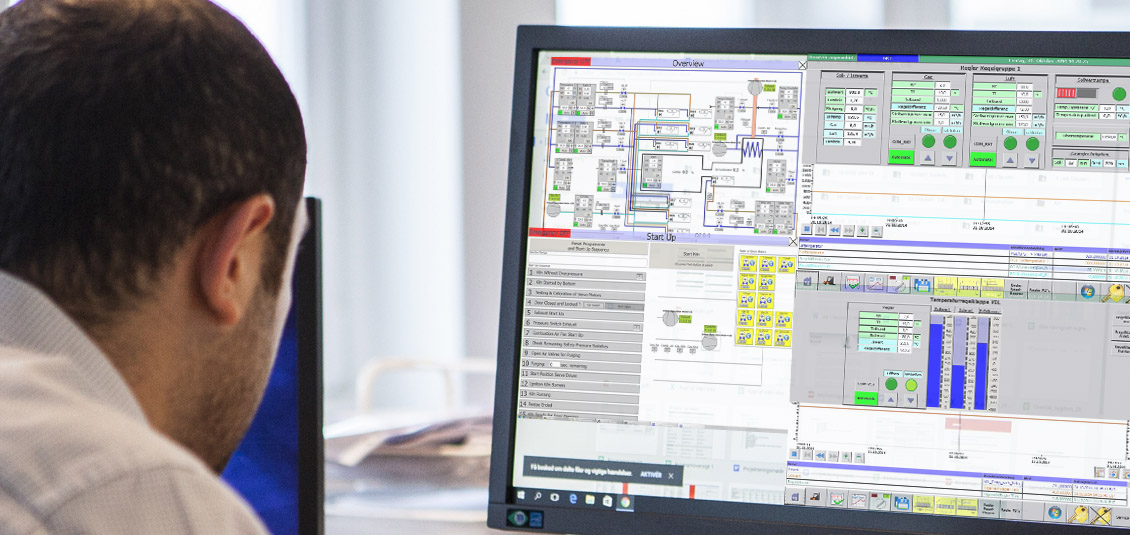

The development of technical ceramic(s), Advanced Ceramic, fireproof ceramic(s) etc. - progresses dynamically. New products often require for new technologies. Our goal is to design for you an individual kiln plant with which you produce optimal product properties. Massive developments have been necessary to take the simplest designs, used for basic porcelain production, to a level capable of sintering pure alumina parts at 1850°C. German Kiln Technology (GKT) is a major supplier of sintering lines and kilns for producing all kinds of technical ceramics, such as: For the firing process GKT offers the most diverse selection of equipment, dependant on capacity and procedure, operating electrically or with fossil fuels:

Type of products to sinter

German Kiln Technology (GKT) is a major supplier of sintering lines and kilns for producing all kinds of technical ceramics, such as:

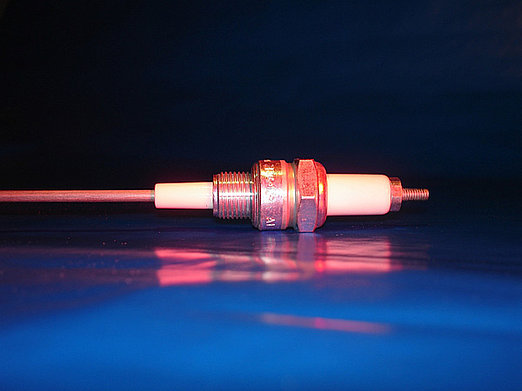

- Struktur- und Elektronikkeramik

- LTCC Keramik

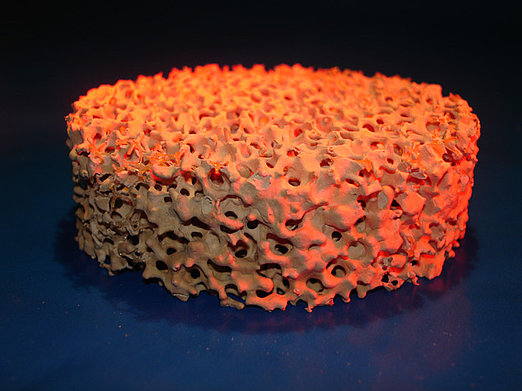

- Katalysatoren und Filter für die Automobil- und chemische Industrie

- Medizinkeramik

- Hochreine Al2O3 und Zirkonoxidprodukte

- Keramikfilter

- Passive und aktive Funktionskeramik

- Schleifscheiben und Schneidwerkzeuge

- Mahlkugeln

- Hochspannungsisolatoren

- Schüttgutkatalysatoren

Choice of kiln to use

- Shuttle, chamber, bell type and lifting hearth kilns to 2000°C

- Tunnel kilns to 1850°C

- Roller kilns to 1650°C

- Mesh belt kilns to 1000°C

- Tempering kilns to 350°C

- Incineration units and thermal Incinerating units to 1200°C

Talk to us, we listen and help.