Automation

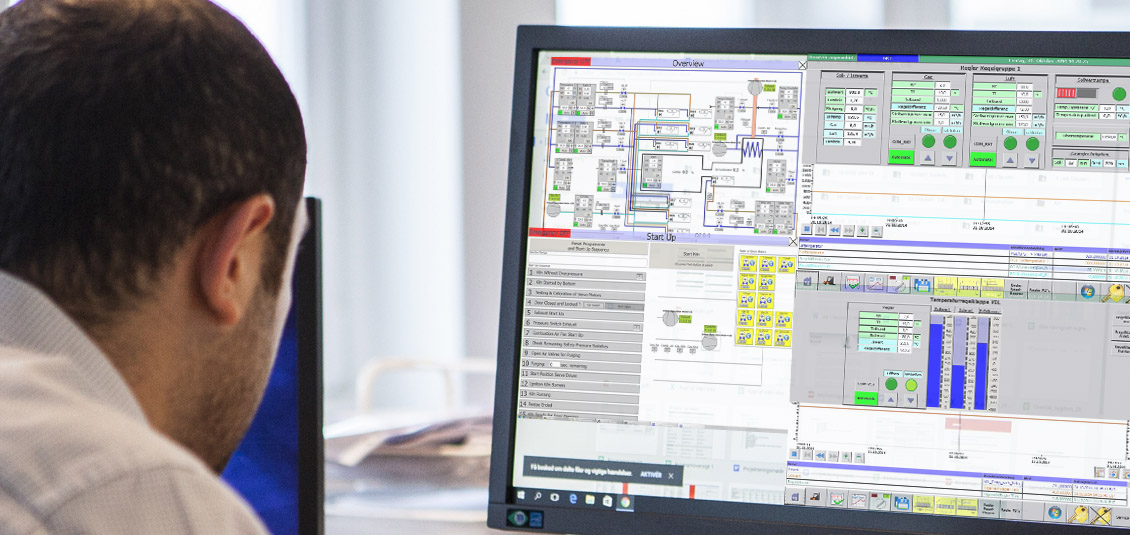

Automation and handling systems are increasingly supporting production processes. Material flows are recorded, errors avoided and processes improved. Reproducibility, process reliability and 100% availability are just some of the keywords that characterise automation. Finally, smart and sensible automation can result in significant cost savings, creating competitive advantages that significantly impact your bottom line.

We are supported by Münsterman and offer the most different concepts to you.

Settling and calibration plant for refractory bricks

The functions in detail

- Unloading and placing the refractory bricks from a kiln car to a linear conveyor

- Calibration (height measurement), signing (calibration class, designation or similar) and marking of the stones

- Palletizing the stones according to the calibration class on wooden pallets

It can be set a variety of stone formats with the plant. The control is customised. An example is the specially programmed setting pattern generator. The operator can thus adjust the setting pattern for the different stone types at the touch of a button. Robots then ensure optimum stacking of the stones on the kiln cars or pallets.

Bypass plant with traverser

An example of the interest exchange:

Oven bypass for new refractory brick plant in China

Transfer platform shortly before taking over a kiln car

One of the most modern Chinese factories for the production of refractory bricks for the cement and steel industry relies on automation solutions and handling components from Münstermann.