自动化

自动化的生产和自动化转运系统和机械手在生产流程中起着关键作用,是对制品状况信息的及时获取。

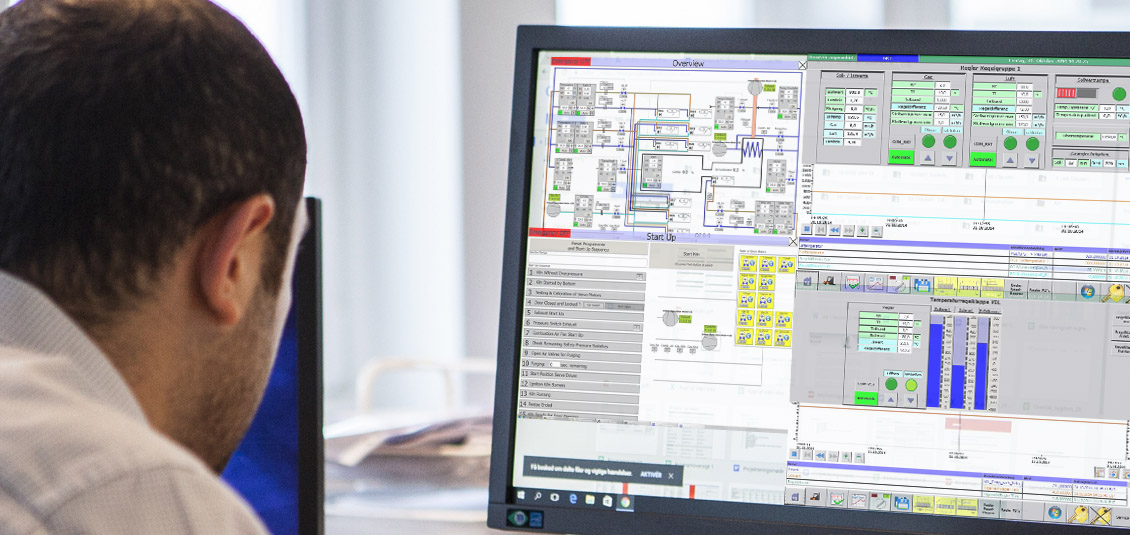

这对降低生产成本是一个不可或缺的条件。要想实现生产流程的安全性,缺陷产品的及时发现及修复,其关键就是一块占地不大的自动化控制室。其综合效果就是成本的降低并令你在竞争激烈的市场中处于优越位置.

德国窑炉技术公司GKT在自动转运系统和机械手方面与密切友好协作公司德国明斯特曼Münstermann 一起合作按照不同客户的个性化要求为用户提供此自动化的设计和设备。

德国窑炉技术公司的窑炉和明斯特曼的转运系统在中国成功运用事例

在中国河南巩义为水泥和钢铁行业生产耐火材料的我司客户一家现代化工厂里,他们采用了与我司高温隧道窑烧结运行系统相匹配的明斯特曼的自动化转运系统,此系统得到客户满意良好评价。

Settling and calibration plant for refractory bricks

The functions in detail

- Unloading and placing the refractory bricks from a kiln car to a linear conveyor

- Calibration (height measurement), signing (calibration class, designation or similar) and marking of the stones

- Palletizing the stones according to the calibration class on wooden pallets

It can be set a variety of stone formats with the plant. The control is customised. An example is the specially programmed setting pattern generator. The operator can thus adjust the setting pattern for the different stone types at the touch of a button. Robots then ensure optimum stacking of the stones on the kiln cars or pallets.

Bypass plant with traverser

An example of the interest exchange:

Oven bypass for new refractory brick plant in China

Transfer platform shortly before taking over a kiln car

One of the most modern Chinese factories for the production of refractory bricks for the cement and steel industry relies on automation solutions and handling components from Münstermann.