Refractory bricks

Some ranges of the refractory industry shifted like many other ranges to Asia. Still fireproof materials are needed generally speaking extent traditionally for the steel industry. German Kiln Technology (GKT) focusiert its activities on these markets however without the contact to the European economy to neglect.

The world-wide large fireproof manufacturers rank already now among our business partners. Our kiln plants are used for the entire fireproof pallet such as Silica, refractory clay, high Al2O3 content of products, magnesite, chromium magnesite, dolomite, NSiC and new mixture products.

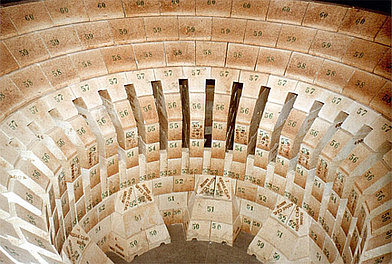

Just like with technical ceramic reaching optimal product properties makes high demands against the kilns. Accurate processing, temperature distribution and temperature uniformity are conditions for basis, in order to sinter an excellent product.

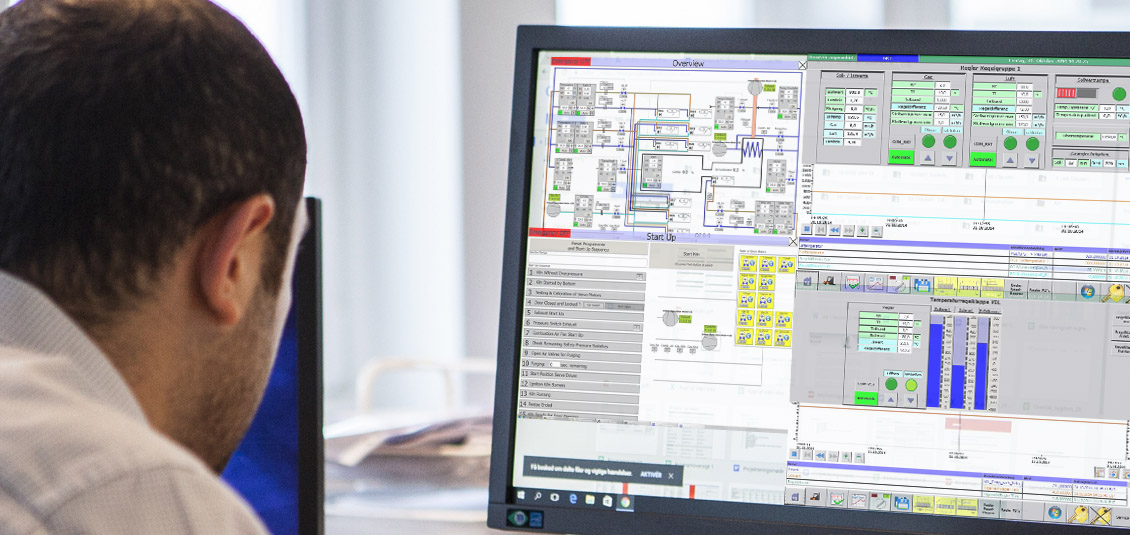

GKT optimizes fuel processes, designs burner those the fuel process to be adapted and develops new control systems. Our burners - with or without secondary air mixing - are designed for very high combustion air temperature > 550°C. The burner systems fulfil the high requirements of TA-Luft (Technical Instructions on Air Quality Control).

Constant research and optimization of our products secure your achievement.

Energy saving and heat recovery is another major point beside the product. Creation of value is more than only yield.

Choice of kiln to use

- Shuttle kilns to 1850°C

- Tunnel kilns to 1850°C

- Roller kilns to 1650°C

- Tempering kilns to 350°C for special tar and resin bonded MgO bricks

- Thermal incinerating units, thermal oxidizer to 1200°C

We are always at your disposal, so speak with us for expert advice.